REVERSE ENGINEERING

A process to develop CAD data from physical components. One could recover designs, requirement specifications and functions of a product from an analysis of its code. It builds a program database and generates information from this.

The purpose of reverse engineering is to facilitate the maintenance work by improving the understandability of a system and to produce the necessary documents for a legacy system. It gives out solution to issues like coping with Complexity, recovering lost information, synthesise higher abstraction and more.

Video Message from our Founder, Anand Bellad

Why Arun 3D Labs!

Reverse Engineering is process used to develop CAD data from physical components. This data can further be used to extract tooling, CAE analysis, Rapid Prototyping, Bench Marking, Core-Cavity Replication, Pattern Replication, and many such applications.

Scanned Data ----> Surface CAD Data ----> Solid CAD data

We derive manufacturing tolerances from the scanned data and built CAD from from it.

We can build CAD data of any material. Or company knowledge base is not confined to any specific material. We can build manufacture able CAD data of castings, plastic, wax, foam, etc.

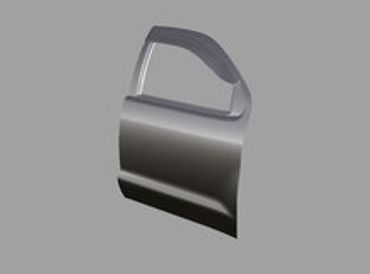

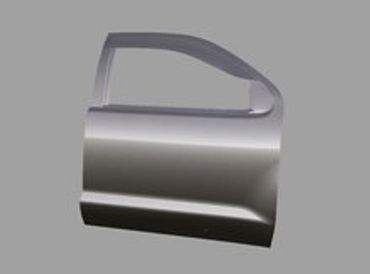

Class-A Surfacing Sheet Metal

Casting Cylinder Head

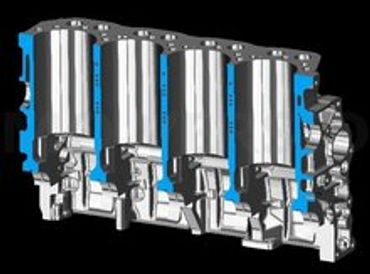

Casting Manifold

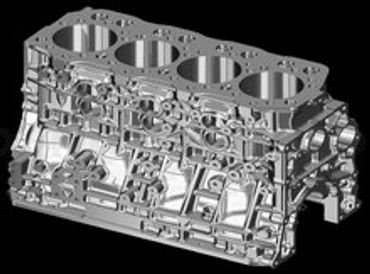

Casting Cylinder Block

Dashboard Design

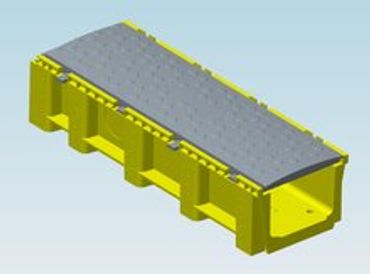

Plastic-Agri Industry

Plastic-Consumer Durables

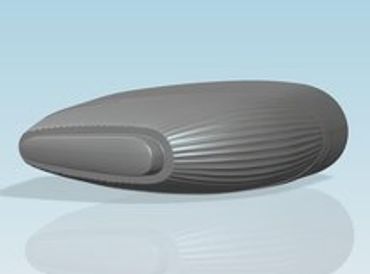

Reverse Engineering Rubber Parts

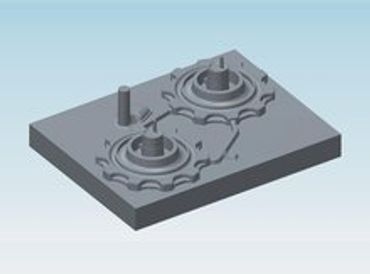

Reverse Engineering- Tooling

designed & maintained by VISION KRAFT

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.